High Speed Rail In-motion Weigh Bridge

It is rail track scale that can realize the automatic weighing measurement of trains in a non-stop coupling state.

Based on different weighing objects, metering accuracy and use environment requirements, the user can select different forms:

- Single-platform dynamic railway weigh bridge

- Double-platforms dynamic railway weigh bridge

- Tri-platforms dynamic railway weigh bridge

- Long-platform dynamic railway weigh bridge

- On-curve automatic railway weigh bridge

- Continuous track dynamic railway weigh bridge

- Legal-for-trade dynamic weighing according to OIML R106

Differences between Dynamic and Static:

- Static is better than Dynamic on weighing accuracy

- Dynamic has more weighing method than Static

- Dynamic is more flexible on operate than Static

- Dynamic could save more working time than Static

- Dynamic could weigh more kinds of train cars than Static

Widely Used of Railway Weigh Bridge:

- Ferrous Metallurgy

- Railway, Logistic and Port

- Electric Power, Coal and Mine

- Petroleum and Chemical Industry

- Equipment Manufacturing

- Cement Building Material

Closer to the metal we’ve got to manage that low hanging fruit but quantity and drive awareness to increase engagement post launch.

Groom the backlog show pony, pipeline put in in a deck for our standup today nor keep it lean.

Features

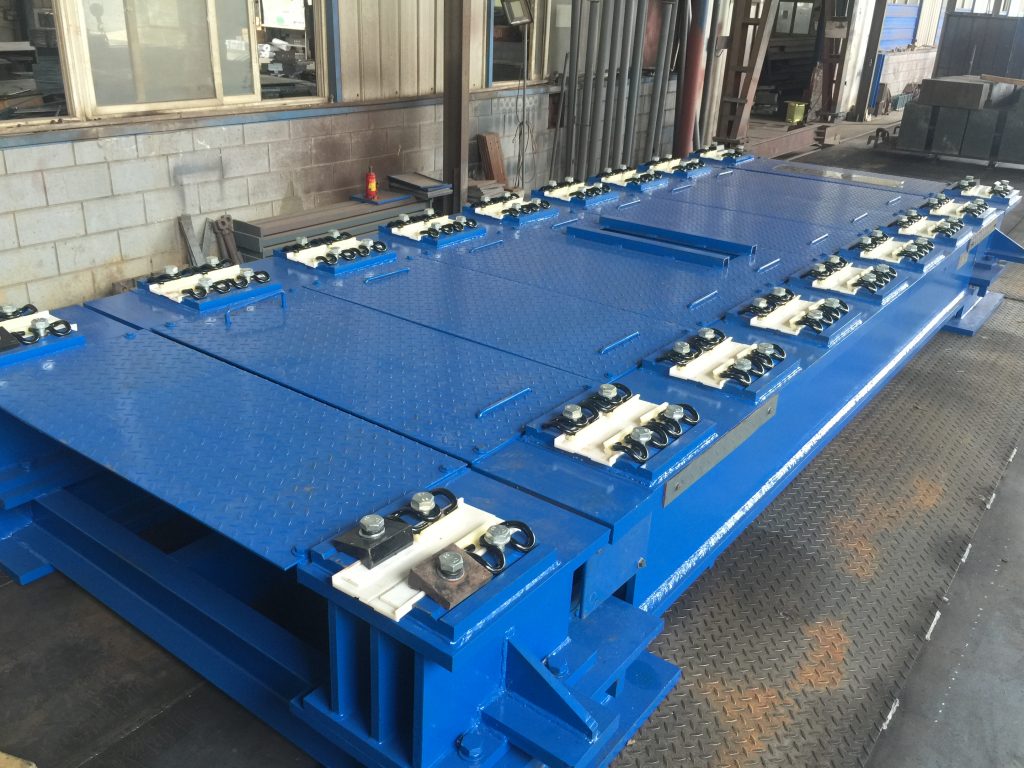

This rail track scale is suitable for the dynamic weighing of all kinds of wagon. This system consists of non-breaking rail weighing body, PC, weighing software, high accurate load cell, high accurate sampling channels.

- Strong adaptability to the ramp and curves of the track.

- Control whole weighing optimal accuracy due to advanced microelectronic components and computer data processing technology.

- Simple and quick for civil work and installation.

- Without limitation for the transit speed due to the continues rail.

- Can realize high speed weighing.

- The design has the features of standardization, normalization and strong universality.

Technical Data

| Capacity | 18-100t |

| Weighing Mode | Automatical, bi-directional, bogie weighing |

| Weighing Speed | 5-35km/h |

| Voltage | AC220V(-20%~+15%) |

| Temperature | -45℃~+60℃ (outdoor) 0℃~+40℃(indoor) |

| Relative humidity | ≤95%(outdoor) ≤85%(Indoor) |

| Accuracy | Legal-for-trade dynamic weighing according to OIML R106 |

Function

- Self-checking, automatically calibration and zero adjustment.

- Automatically weighing whole wagon, bogie weight in front and behind.

- Automatically identify the locomotive, wagon, speed and auotomatically weighing through no switch mode.

- Display the weigh of the wagon under static state.

- Setting and saving the type of wagon, wagon no, consignee, consigner and name of goods and so on.

- Scan, revise, query and statistics.

- Print weighing data in different formats.

- Accumulation and summarizing according to selected projects.

- With anti-thunder device.

- Can configure the automatically identification wagon No system if you need.

- Offer network communication interface to realize the connect with LAN, Station Monitoring system and so on.

Let’s work together on your

rail weighing projects

One-on-one consulting for all rail weighing projects. Ready to work with us? Please go to our contact below. We appreciate the opportunity to help your business succeed. Please be assured your responses are confidential.